#HDPE injection molded

Explore tagged Tumblr posts

Text

The Advantages of Injection Molded Pallets: Durability, Efficiency, and Sustainability in Logistics

Pallets play a crucial role in the logistics world and, as such, picking out the right ones can be hard when you want to strike that perfect balance between efficiency and sustainability.

Injection molded pallets provide durability, light weight and are environmentally friendly which has made them the optimal choice for most businesses seeking ways to make their operations run smoothly.

1. Durability You Can Rely On Injection molded pallets are made from HDPE, which resists moisture, chemicals, and UV rays. It is especially heavy-duty for maximum load capacity. Unlike traditional pallets, they won’t splinter or rot, ensuring safe transportation and reducing replacement frequency. Additionally, this durability means less downtimes and supply chain interruptions.

2. Lightweight for Enhanced Efficiency Pallets are lighter than metal options, which makes them easier to handle and stack. This lightweight design may maximize storage efficiency and reduce shipping rates that helps overall operations in terms of performance. It is also easy to maneuver that can result in quick load and unload times, promoting faster productivity as well.

3. Environmentally Friendly Solution Injection molded pallets are often made from recycled HDPE and are fully recyclable themselves. An environmentally conscious method by its nature reduces waste and resource utilization with time, this fits right into the sustainability objectives. By choosing these pallets, businesses can also demonstrate their commitment to environmentally responsible practices to their customers.

4. Versatile Applications

These pallets are most commonly used in the pharmaceutical and food industry as they ensure cleanliness, hygiene, and can be manufactured with a material that suits customers’ requirements. This makes them more versatile and useful for a range of products across various packaging dimensions.

5. Cost-Effectiveness Over Time Although initial cost is relatively higher, the longevity and low weight of this material can result in significant savings due to high-resistance pallets allowing lower replacement rates and reduced shipping expenses. This means saving over the long haul. In the end, these pallets can even help to boost your business’s bottom line.

6. Our versatile HDPE Pallets Offering: Our HDPE injection-molded pallets include the SIP-M24–1212DH, SIP-M24–1210DM, and SIP-M24–1212NH models. Each is durable and versatile, with the SIP-M24–1212DH featuring a double-sided design, the SIP-M24–1210DM being lightweight and robust, and the rackable SIP-M24–1212NH suitable for heavy racking and lightweight cargo packaging. All are made from high-density polyethylene for maximum resistance.

Conclusion

Businesses looking for a blend of sustainability and economy will make the perfect investment with Swift Technoplasts’s injection molded pallets. They can raise the bar with durability and sustainability to any operations in logistics, thus being a practical solution for long-term saving.

#Injection Molded Pallets#Durable Plastic Pallets#Sustainable Pallets for Logistics#Lightweight HDPE Pallets#Recyclable Pallets for Supply Chain#Cost-Effective Pallets#Pallets for Warehouse Efficiency#Plastic Pallets for Shipping#HDPE Pallets Manufacturer#Pallets for Material Handling#Heavy-Duty Rackable Pallets#HDPE injection molded#plastic pallets

0 notes

Text

UHMWPE lining sheet,road mats,soccer rebounder board.plastic cut to size....

Dezhou New Origin Rubber&Plastic CO.,Ltd. is located at the China polyethylene engineering plastic products intensive center, Dezhou City, close to Beijing and Tianjin City. We are engaging in the engineering plastics from 1996.

Kelly Wei

Sales Manager

Email:[email protected]

Cell:+86 17705445030

Whatsapp: +86 17705445030

Website:www.dz-neworigin.com

Our plastic products cover a full range from semi-finished sheets to various machined parts, including CNC machining parts, injection molding parts, marine fender pads, lining sheet, temporary road mats, outrigger pads, synthetic ice rink, curling lanes, cutting board,soccer rebounder boards, as well as plastic irregular machinery parts, which are widely used in marine system, mining, construction, events and projects, sports, food and machinery industries. Which have been exported to United States, United Arab Emirates, India, Russia, Australia, Ukraine, Lithuania, Peru, Germany, Spain Saudi Arabia, South Africa etc. All the customers give good appreciation to our products.

2 notes

·

View notes

Text

Manufacture of Plastic Bottles and Plastic Caps

Plastic bottles and caps are essential packaging solutions used across industries such as beverages, pharmaceuticals, personal care, and household products. SupplePack specializes in the high-quality manufacturing of plastic bottles and caps, ensuring durability, safety, and sustainability.

Manufacturing Process of Plastic Bottles

1. Material Selection

The process begins with selecting the right plastic resin, typically PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), or PP (Polypropylene). These materials are chosen for their strength, flexibility, and recyclability.

2. Injection Molding (Preforms)

For PET bottles, preforms are first created using injection molding. Plastic pellets are melted and injected into preform molds, forming small test-tube-like shapes that will later be blown into bottles.

3. Stretch Blow Molding

The preforms are heated and placed in a blow molding machine, where high-pressure air stretches and expands them into the desired bottle shape. This ensures uniform thickness and structural integrity.

4. Cooling and Trimming

The newly formed bottles are cooled to retain their shape. Excess plastic (flash) is trimmed off, and the bottles undergo quality checks for leaks or deformities.

Manufacturing Process of Plastic Caps

1. Injection Molding

Plastic caps are produced using injection molding, where molten plastic is injected into cap-shaped molds under high pressure. Common materials include PP or HDPE for durability.

2. Cooling and Ejection

Once molded, the caps cool and harden before being ejected from the molds. They may undergo threading or lining (for tamper-evident or sealing features).

3. Quality Testing

Caps are inspected for defects, proper fit, and functionality. Some caps include child-resistant or flip-top mechanisms for specialized applications.

SupplePack’s Commitment to Quality & Sustainability

Eco-friendly materials: Use of recycled plastics and biodegradable options where possible.

Advanced manufacturing: Precision engineering for leak-proof and durable packaging.

Customization: Tailored designs, colors, and functionalities to meet client needs.

SupplePack ensures efficient, sustainable, and high-quality production of plastic bottles and caps, catering to diverse industry requirements while minimizing environmental impact.

Would you like additional details on specific bottle types or customization options?

0 notes

Text

0 notes

Text

Applications of Vietnam Transparent Filler Masterbatch

Specifically, It is widely used in various plastic production processes, such as:

Blown film extrusion (HDPE, LDPE, LLDPE)

Injection molding

Thermoforming

Sheet extrusion

Not only does it improve processing performance, but it also enhances mechanical strength and reduces raw material consumption. Consequently, production becomes more efficient and cost-effective.

0 notes

Text

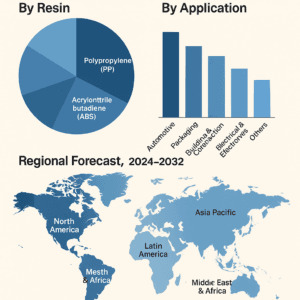

Injection Molded Plastics Market Key Developments and Forecast to 2032

According to Fortune Business Insights™, the global injection molded plastics market size was USD 387.51 billion in 2023 and is projected to grow from USD 403.85 billion in 2024 to USD 561.58 billion by 2032 at a CAGR of 4.2% during the 2024-2032 period. Asia Pacific dominated the injection molded plastics market with a market share of 49.25% in 2023. This information is published by Fortune Business Insights™, in its report titled, “Injection Molded Plastics Market, 2024-2032.”

According to our researchers, few of the principal uses of the product are in automobile, packing, building & construction, medical, electrical & electronics and other industries. They are majorly used in the packaging industry for making containers, food packaging, bottles for cosmetics and pharmaceutical products, and different types of closures. Injection molding is the manufacturing process for the fabrication of plastics. Some of the major applications are automotive, packaging, building & construction, electrical & electronics, medical, and others. They are majorly used in the packaging industry for making containers, food packaging, bottles for cosmetics and pharmaceutical products, and different types of closures. Plastic is also an ideal material for electronics products as it can be conducive, as well as non-conductive plastic, UV resistance, rigid and flexible, and also available in various colors.

Get a Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/injection-molded-plastics-market-101970

List of Key Players Covered in the Report

BASF SE (Germany)

Dow Inc. (U.S.)

DuPont (U.S.)

HTI Plastics (U.S.)

LyondellBasell (Netherlands)

Coastal Plastic Molding, Inc. (U.S.)

Huntsman Corporation. (U.S.)

Magna International Inc.(Canada)

Report Coverage

We provide our reports which are conducted with an all-inclusive examination approach that majorly emphasizes on delivering precise material. Our scholars have applied a data triangulation method which further assists us to offer trustworthy estimations and test the general market dynamics accurately. Further, our analysts have received admission to numerous international as well as regional funded registers for providing the up-to-date material so that the stakeholders and business professionals invest only in essential zones.

Segmentation

On the basis of resin, the global market for injection molded plastics is bifurcated into Polypropylene (PP), Acrylonitrile butadiene styrene (ABS), High-density polyethylene (HDPE), Polystyrene (PS), and Others.

Based on application, the market is further divided into Automotive, Packaging, Building & Construction, Electrical & Electronics, Medical, and Others. The packaging segment held the largest share in this market. This segment is driven by food & beverages, pharmaceutical, and retail applications.

In terms of geography, the market for injection molded plastics is segregated into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Drivers and Restraints

Innovation in Injection Molding Technologies is a Prominent Trend

There has been incessant improvement in technologies regarding injection molding such as the increasing predisposition towards incorporated method to product design which has accentuated the production operation. This has further tapered down the space between the structuring and production stage, principally in case of complicated products, such as medical apparatuses. This is famously known as micro injection molding in production of medical apparatuses where the procedure is engaged at a microscopic level. This is expected to boost the injection molded plastics market growth during the forecast period.

Regional Insights

Escalating Product Demand to Boost Growth in Asia Pacific

Asia Pacific is estimated to hold majority of the injection molded plastics market share and endure as a dominant region in the market during the mentioned period owing to the increasing demand for the product from the packaging and automobile industries. The market size of Asia Pacific was USD 162.98 billion in 2020.

The demand for injection molded plastics in North America is projected to upsurge owing to an abrupt demand from the packaging and electronics industries based in this region.

Europe is expected to hold a substantial share in the market. Growing demand for appropriate packaging for food and beverages have prolonged the visualization of packaging goods producers.

Information Source: https://www.fortunebusinessinsights.com/injection-molded-plastics-market-101970

Competitive Landscape

Key Players to Fortify their Positions by Offering New Product Solutions

Principal producers are situated in Asia Pacific, which is leading to a bifurcated injection molding market. The manufacturers positioned in North America and Europe are concentrating towards reinforcing their market positions in several nations in Asia Pacific set to fuel the growth of their respective establishments. Fundamental players in the market such as BASF SE, HTI Plastics, DuPont, and others have advanced robust regional attendance, distribution channels, and product offerings.

Key Industry Developments

February 2024: Kreate announced its takeover of a supplier of injection molded plastics based in Georgetown, TX. The move is anticipated to significantly enhance the production capacity of the company and enhance its logistics network.

August 2020: Avient Corporation (Formerly PolyOne) introduced injection moldable thermoplastic elastomers to its Versaflex series. The product was formulated without animal derivatives and is able to serve a variety of medical device applications.

0 notes

Text

5 Top Packaging Companies in the Philippines

If you're exploring more dependable packaging suppliers in the Philippines, these five companies are worth your attention. Known for their specialization, quality, and regional reach, they complement the top-tier list by offering tailored packaging solutions across various industries.

Entrepouch – Your One-Stop Flexible Packaging Solution

Number #1 packaging company in Entrepouch tops our list for a reason—it offers a wide variety of high-quality, customizable, and cost-effective pouches and packaging solutions for businesses of all sizes. Whether you're in food and beverage, cosmetics, supplements, or retail, Entrepouch provides:

• Flat and Stand-Up Pouches (silver, gold, white, transparent)

• Vacuum Bags and Resealable Zippers

• Food-Grade, Durable, and Eco-Friendly Materials

• Custom Printing & Bulk Orders

• Nationwide Delivery Across the Philippines

With a strong reputation for excellent customer service and fast order fulfillment, Entrepouch is the go-to partner for thousands of local brands aiming for shelf-ready appeal and long-lasting packaging performance.

Jumbopack Industries Corporation

Jumbopack Industries is a leading manufacturer of plastic packaging products with a strong focus on food-grade containers, bottles, and jars. They cater to both SMEs and large food processing plants, ensuring durable and safe packaging for liquids, powders, and granules.

Key Products:

HDPE and PET bottles

Plastic jars and containers

Custom injection molding

Best For: Beverage, condiments, personal care products

Advanced Flexible Packaging Solutions, Inc.

This company specializes in flexible laminated packaging, particularly for food and beverage applications. Advanced Flexible Packaging Solutions offers roll stocks, sachets, and pouches with high barrier protection, ideal for extending shelf life.

Highlights:

Rotogravure printing up to 9 colors

High-barrier laminate films

Custom pouch formats (three-side seal, stand-up, spouted)

Best For: Coffee, snacks, dairy, and pet food packaging

Nature’s Legacy Packaging

Sustainability meets functionality at Nature’s Legacy, a pioneer in eco-friendly and biodegradable packaging solutions in the Philippines. They use innovative materials like stone paper and natural resin composites for unique packaging forms.

Key Offerings:

Sustainable packaging made from agricultural waste

Compostable and biodegradable materials

Custom-designed retail and gift packaging

Best For: Green brands, organic product lines, and eco-conscious retailers

Tritec Packaging Systems and Solutions Inc.

Tritec Packaging provides end-to-end packaging solutions, including machinery, automation systems, and consumables. Their wide range of packaging equipment makes them a preferred partner for growing businesses that need scalable solutions.

Services Include:

Shrink wrapping and labeling machines

Filling, capping, and pouch sealing systems

Packaging line integration

Best For: Medium to large-scale manufacturers

Polytrade Packaging Corporation

Established in the 1970s, Polytrade Packaging has decades of experience providing paper-based packaging such as folding cartons, corrugated boxes, and paper bags. They serve industries ranging from pharmaceuticals to consumer goods.

What They Offer:

Custom printed paper boxes

Food-grade paper packaging

Export-quality cartons and inserts

Best For: Cosmetics, pharmaceuticals, retail goods

0 notes

Text

Bán máy móc ngành nhựa – Giải pháp toàn diện cho doanh nghiệp sản xuất nhựa hiện đại

Trong thời đại công nghiệp hóa – hiện đại hóa, ngành sản xuất nhựa đang có tốc độ tăng trưởng mạnh mẽ, kéo theo nhu cầu về thiết bị, máy móc hiện đại phục vụ sản xuất ngày càng cao. Bán máy móc ngành nhựa hiện đang là một lĩnh vực tiềm năng, cung cấp giải pháp đồng bộ giúp các nhà máy tối ưu chi phí, tăng năng suất và cải thiện chất lượng sản phẩm.

1. Máy móc ngành nhựa gồm những gì?

Máy móc ngành nhựa rất đa dạng, được chia thành nhiều nhóm thiết bị khác nhau, phục vụ từng công đoạn trong quá trình sản xuất:

🔹 Máy gia công nguyên liệu nhựa

Máy sấy nhựa (máy hút ẩm): Loại bỏ hơi ẩm trong hạt nhựa giúp nhựa không bị bọt khí khi ép.

Máy hút liệu (máy hút hạt nhựa): Vận chuyển hạt nhựa từ thùng chứa lên phễu máy ép tự động.

Máy trộn nhựa: Trộn đều các loại nhựa và phụ gia theo tỉ lệ mong muốn.

🔹 Máy tạo hình sản phẩm

Máy ép nhựa (injection molding): Tạo ra các sản phẩm nhựa chính xác từ khuôn đúc.

Máy thổi nhựa (thổi chai HDPE, PET): Sản xuất chai nhựa, bình, can nhựa…

Máy đùn nhựa: Tạo các sản phẩm dạng thanh, tấm, ống nhựa…

🔹 Thiết bị phụ trợ và tự động hóa

Máy làm nóng khuôn, làm mát khuôn (chiller, mold heater).

Cánh tay robot gắp sản phẩm nhựa: Hỗ trợ tự động lấy sản phẩm ra khỏi máy ép.

Máy nghiền, máy xay nhựa tái chế: Tái sử dụng nhựa phế liệu, tiết kiệm chi phí.

2. Vì sao nên chọn đơn vị bán máy móc ngành nhựa uy tín?

Việc lựa chọn đúng đơn vị cung cấp máy móc chất lượng, dịch vụ hậu mãi tốt sẽ giúp doanh nghiệp:

✅ Tối ưu chi phí đầu tư ban đầu: Có nhiều lựa chọn phù hợp ngân sách, được tư vấn đúng thiết bị theo nhu cầu thực tế.

✅ Vận hành ổn định: Thiết bị đạt chuẩn chất lượng, linh kiện chính hãng, ít hư hỏng, hạn chế thời gian dừng máy.

✅ Hỗ trợ kỹ thuật nhanh chóng: Được hỗ trợ lắp đặt, hướng dẫn vận hành, bảo trì định kỳ và sửa chữa kịp thời.

✅ Cập nhật công nghệ mới nhất: Được giới thiệu và tiếp cận sớm với các dòng máy tiên tiến, tiết kiệm điện, dễ điều khiển.

3. Tiêu chí chọn nơi bán máy móc ngành nhựa

Nếu bạn đang tìm đối tác cung cấp thiết bị, hãy cân nhắc các yếu tố sau:

🔸 Thương hiệu phân phối: Nên chọn nhà cung cấp đại diện các thương hiệu nổi tiếng như Haitian, Yizumi, Wensui, Topstar...

🔸 Kinh nghiệm trong ngành: Đơn vị nhiều năm kinh nghiệm sẽ hiểu rõ quy trình sản xuất và tư vấn sát nhu cầu.

🔸 Chế độ bảo hành – hậu mãi rõ ràng: Cung cấp phụ tùng thay thế, cam kết bảo hành máy từ 12–24 tháng.

🔸 Dịch vụ lắp đặt – vận hành: Có đội ngũ kỹ thuật hỗ trợ tận nơi, giúp máy hoạt động đúng quy trình ngay từ đầu.

🔸 Giá cả hợp lý, minh bạch: Không phát sinh chi phí ẩn, có nhiều lựa chọn phù hợp quy mô từ nhỏ đến lớn.

4. Đối tượng nên đầu tư máy móc ngành nhựa

Các cơ sở sản xuất nhựa hộ gia đình đang muốn nâng cấp thiết bị.

Nhà máy nhựa công nghiệp mở rộng quy mô, tăng năng suất.

Các xưởng sản xuất bao bì, chai lọ, linh kiện điện tử nhựa…

Doanh nghiệp khởi nghiệp trong lĩnh vực ép nhựa, nhựa tái chế.

5. Chúng tôi chuyên bán máy móc ngành nhựa toàn quốc

Với kinh nghiệm nhiều năm phân phối thiết bị ngành nhựa, chúng tôi cam kết:

✔️ Cung cấp đầy đủ dòng máy: máy ép, máy thổi, robot, chiller, máy xay nhựa, máy sấy… ✔️ Hàng chính hãng – chất lượng ổn định – bảo hành 12–24 tháng. ✔️ Hỗ trợ vận chuyển, lắp đặt tận nơi, vận hành thử miễn phí. ✔️ Có sẵn linh kiện, phụ tùng thay thế – sửa chữa nhanh chóng. ✔️ Tư vấn giải pháp đồng bộ cho từng quy mô nhà máy.

6. Kết luận

Việc đầu tư đúng máy móc ngành nhựa chính là chìa khóa giúp doanh nghiệp tăng năng suất, giảm chi phí, nâng cao chất lượng sản phẩm và đáp ứng được yêu cầu ngày càng cao của thị trường. Nếu bạn đang có nhu cầu mua – bán máy móc ngành nhựa, hãy tìm đến đơn vị uy tín để được tư vấn và hỗ trợ tốt nhất

0 notes

Text

Supplier of PET Bottle Scrap Washing Line

R Mech Machine LLP is a leading and prominent Manufacturer, Exporter and Supplier of PET Bottle Scrap Washing Line in Jharkhand and Odisha. Our manufacturing unit is based in Ahmedabad, Gujarat, India. R Mech Machine LLP provides PET Bottle Scrap Washing Line, HDPE/PP/PVC/PPCP Scrap washing line, LDPE/PP Film Scrap Washing Line. We design our machines for high performance, durability, and versatility to meet the ever-growing demands of the global recycling industry. We engineer this line to process post-consumer PET bottles into clean PET flakes, ideal for reuse in textiles, packaging, and more. This washing line efficiently processes rigid plastics like detergent bottles, milk jugs, and industrial plastic waste into clean, recyclable granules. We specifically designed it for handling soft plastics such as agricultural films, shopping bags, and packaging films. Features: Automated Control System: Smart PLC-based control panels for efficient and user-friendly operation. High-Efficiency Friction Washers & Float-Sink Tanks: Advanced washing technology ensures optimal separation and cleaning. Stainless Steel Contact Parts: Rust-resistant and food-grade compliant components. Energy-Efficient Design: Optimized motors and low-energy consumption systems reduce operating costs. Robust Construction: Built with premium-grade materials to ensure durability in demanding environments. Benefits: Superior Cleaning Efficiency: Delivers high-purity output with minimum residual contamination. Reduced Labor Costs: High degree of automation minimizes manual intervention. Flexible Input Material Handling: Capable of processing mixed, colored, and printed plastic waste. Minimal Water Usage: Closed-loop water systems ensure reduced water consumption and better environmental performance. Long Service Life: Heavy-duty design and minimal maintenance ensure consistent long-term operation. Return on Investment: Increases profitability through efficient plastic recovery and resale. Applications & Uses: Textile Industry Packaging Sector Film Extrusion Injection Molding Waste Management Firms FAQs Q1: What materials can be processed in a single washing line? A1: We offer both mono and multi-material configurations, depending on the customer’s input material and end use. Q2: Can your lines be customized to fit space constraints? A2: Yes, our engineers design modular systems tailored to specific space and capacity requirements. Q3: What is the typical installation time? A3: Depending on complexity, installations take 20 to 60 days from the date of site readiness. Q4: Do you offer operator training? A4: Yes, we provide comprehensive on-site or remote training with detailed operational manuals. R Mech Machine LLP is a Supplier of PET Bottle Scrap Washing Line in Jharkhand and Odisha including locations Ranchi, Jamshedpur, Dhanbad, Hazaribagh, Bokaro, Deoghar, Koderma, Giridih, Garhwa, Gumla, Bhubaneshwar, Cuttack, Rourkela, Angul, Mayurbhanj, Puri, Sambalpur, Brahmapur. Contact us today for a free consultation or a quote. View Product: Click here Read the full article

0 notes

Text

Exploring the World of Plastic Jar Manufacturers: A Friendly Guide

When thinking about everyday essentials, plastic jars might not be the first thing that comes to mind. Yet, they’re all around us—holding our favorite snacks, kitchen spices, cosmetics, and even health supplements. Behind these handy containers are plastic jar manufacturers who ensure durability, convenience, and safety. Let’s take a closer look at what goes into making these versatile jars and why they matter.

Why Plastic Jars?

Plastic jars have become a staple across industries due to their lightweight, reusable, and cost-effective nature. Whether for home use or commercial packaging, these jars offer several advantages:

Durability – Less prone to breakage compared to glass.

Portability – Ideal for travel and on-the-go use.

Customization – Available in various shapes, sizes, and colors.

Safety – Often made with food-grade or BPA-free materials.

How Plastic Jar Manufacturers Work

Plastic jar manufacturing is more than just molding plastic into a container. It involves a step-by-step process that blends technology, design, and safety regulations.

1. Material Selection

Manufacturers typically choose from a range of plastics such as:

PET (Polyethylene Terephthalate) – Common for food and beverage storage.

HDPE (High-Density Polyethylene) – Known for strength and chemical resistance.

PP (Polypropylene) – Ideal for microwave-safe containers.

2. Design & Molding

Once the material is selected, manufacturers use methods like injection molding or blow molding to shape the jars. This step ensures precision in:

Wall thickness

Neck finish for caps

Jar capacity and shape

3. Quality Control

Before hitting the shelves, each batch goes through rigorous checks to ensure:

No leaks or cracks

Proper sealing compatibility

Compliance with industry standards

Industries That Rely on Plastic Jars

Plastic jars play an essential role in various sectors, including:

Food & Beverage – For sauces, spreads, and dry snacks

Health & Wellness – For supplements, vitamins, and protein powders

Beauty & Personal Care – For creams, scrubs, and gels

Household & Cleaning – For detergents and cleaners

Their adaptability makes them a top choice for both mass production and small-batch packaging.

Eco-Friendly Practices on the Rise

Modern manufacturers are increasingly shifting towards sustainable solutions such as:

Recycled plastics

Biodegradable alternatives

Refillable packaging options

By embracing eco-conscious practices, the industry is striving to reduce its environmental footprint without compromising on quality.

Final Thoughts

Plastic jar manufacturers might work behind the scenes, but their impact is felt in our daily lives. From pantry storage to bathroom essentials, these jars make organization simple and storage safe. As the industry grows and embraces greener alternatives, plastic jars will likely continue to be a smart and sustainable choice.

Next time you twist open a jar of peanut butter or dip into your favorite face cream, take a moment to appreciate the thoughtful craftsmanship behind that humble plastic container.

0 notes

Text

DM water tank: Protection of Deionized Water

Water is a basic necessity in all industrial establishment, laboratories, pharmaceuticals, electronic manufacturing, and various scientific applications. However, not all water is equal. Producing high purity water needs highly purified demineralized usable as deionized water as a point of supply for end industry. Special tanks designed to store this purified water without any contamination:

DM water: What is it?

DM water, also known as demineralized or, in some cases, deionized water, is water lacking in free ions. To name some ion species included in this group are the common ones- calcium, magnesium, sodium, chloride, sulfate, and carbonate. Ion removal is typically carried out through ion exchange, distillation, or membrane filtration. The end result is water of ultra-high purity and non-conductive designed for industrial and laboratory uses.

Why is a special tank for DM water necessary?

DM water is free from minerals and ions and hence predisposed to absorbing impurities from its surroundings. The stored DM water must not be prone to contaminant absorption the way that it would if stored in regular tanks made of metal and low-grade plastic. Consequently, tanks built solely for DM-water storage must in consideration:

* Be contamination-proof

* Keep water pure

* Resist corrosion and chemical reactions

* Have a guarantee of long-term one-time storage

Main attributes of a DM Water Tank

Features designed to safeguard the quality and security of the stored water should be chosen for the DM water tank. Some of the major properties are:

Non-reactive materials

The majority of DM water tanks are constructed from non-metallic materials, meaning that they might be non-corrosive to HDPE steel or FRP (fiber-reinforced plastic). The basic material should be specially coated with additional stainless steel to prevent the tank from reaction with the water stored therein.

UV Protection

In case of outdoor installations, the tanks should have UV protection against the growth of algae and the degradation of tanks.

Leak Proof design

Should be able to safeguard against 100% leakage to prevent any possibility of losing water and contamination. Tanks that are welded and molded are preferred for safety with tight construction.

Easy maintenance

DM water tanks will be useful for listing reasons given all smooth internal structures and further spontaneous good disinfection possibilities shared, preventing bacterial growth and the formation of biofilms on the internal.

Ventilation and Overflow Control

Appropriate vents and overflow should be designed with proper systems to maintain the tank's pressure balancing and oxidation of airborne particles.

Water through Dissolving Membrane Containers find usages in many conditions where water quality plays a key role.

The common applications are as follows:

1. Laboratory Use

One of the most widespread sources of DM water usage is in research and chemical labs. Some of the works in which it is used include making chemical solutions, rinsing labware, and performing different kinds of experiments. Such tanks are supplied with DM water storage facilities to guarantee that the pure water is supplied.

2. Pharmaceutical Industry

DM water is used as the primary tonic in the preparation of drugs, syrups, and injectable products. It becomes necessary for the otherwise contentious work bad-tasting always to be done accurately and safely along with adequate conduction tanks for transporting DM water as the startup in itself is a risk.

3. Power Plants

In power plants, DM water is used in the boiler feed system to improve heat transfer and efficiency in order to avoid scaling. Proper tanks help safely maintain the water.

4. Electronic and Semiconductor Industry

In electronics, DM water is used for the rinsing and cleaning of parts, most significantly in semiconductor production. Any pollution could lead to much waste and contaminated media; hence using special tanks becomes a necessity.

5. Automobile and Battery Manufacturing

Common uses for DM water are washing cars and filling car batteries with electrolyte.

Advantages of Owning a DM Water Tank

✔ Upsurging Pure Water

The most important perk is maintaining DM water without any added ions, metals, or microbes.

✔Long Lasting and Durable

Most DM tanks are constructed of very high-quality materials that can withstand some mechanical wear and tear, guaranteeing longevity despite the tough environments.

✔Different Sizes Available

Regardless of whether it's an order for 100 liters or 10,000 liters, dim water tanks come in different capacities suitable for many industries.

✔Quick Delivery and Installation

Most of these water tanks can be handled by two or four men, according to capacity; hence, customers save a lot on transportation and labor for erection.

✔Easy on the Expense of Costs

Being a kind of investment regarding the structure of your plant, the tank you put in place will be much cheaper compared with what you will lose to contamination, product wastage, and maintenance.

Selecting the Right Manufacturer or Supplier of DM Storage Tanks

Getting a reliable manufacturer or supplier is as vital a step as selecting the correct tank. Here is an outline of what you should be considering:

Proven track record and experience

Use of certified and food-grade materials

Customizable tank sizes and fittings

After-sales support and maintenance options

Positive customer reviews and references

Usually, a company that does well in the area of building water storage tanks for industrial and chemical enterprises will meet the customer's needs by customizing the storage tank with the specifications based on the need.

DM Water Tanks Maintenance Tips

In order to maintain the life of your DM water tank, the following maintenance routine should be followed:

Cleaning the tank on a frequent basis with non-reactive cleaning agents

Check-up on a regular basis for cracks, leaks or contamination

Have quality seals at inlets, outlets, and vents

Never mix different chemicals in the same tank

Schedule annual inspection by a professional

Future Trends of DM Water Storage

DM water storage solutions are changing as the demand for High Purity Water grows in application-specific industries. Some possible trends are:

Smart tanks that use IoT-enabled sensors for real-time water quality monitoring

Modular tanks to facilitate space-saving installation

Tank materials that are eco-friendly and can be recycled

Integration with automated DM water production systems

Conclusion

DM water tank is more than just a tank for storing water; it is a vital element in preserving integrity and quality of demineralized water. Whether you are in the pharmaceutical, research, or heavy industries, investing in a top-quality DM water tank will ensure that your operations remain efficient, safe, and always in compliance with regulatory standards. In selecting a tank for your works, always give high regard to cleanliness, durability, and proper design to meet the needs of many industries.

0 notes

Text

Choosing the Right Pipes Company in India: A Guide to Quality and Reliability

When it comes to infrastructure, construction, agriculture, and industrial development, one critical component that often goes unnoticed is piping. From water transportation to structural support, pipes play a vital role in the backbone of any development project. As the demand for durable and efficient piping solutions continues to grow, the need to identify the right Pipes Company in India becomes more important than ever.

India's booming construction and industrial sectors have fueled the rapid rise of many pipe manufacturers. Whether for residential plumbing or industrial fluid management, selecting the right company ensures long-term performance, reliability, and safety.

The Growing Demand for Piping Solutions in India

India is experiencing a surge in infrastructural growth, smart city development, and rural water supply schemes. This has naturally led to a high demand for quality pipes in sectors such as:

Construction and Real Estate

Agriculture and Irrigation

Oil and Gas

Water and Wastewater Management

Industrial Processing and Manufacturing

With this demand, choosing a trusted and experienced Pipes Company in India becomes crucial to ensure compliance with safety standards, environmental regulations, and performance expectations.

Types of Pipes Offered by Leading Indian Pipe Companies

A professional Pipes Company in India generally offers a wide range of products to serve different applications. These include:

1. PVC Pipes

Commonly used in plumbing and irrigation systems due to their affordability and corrosion resistance.

2. HDPE Pipes

Known for their high strength-to-density ratio, these pipes are ideal for water supply systems and underground installations.

3. CPVC Pipes

These are perfect for hot and cold water distribution systems in residential and commercial buildings.

4. PPR Pipes

Preferred for industrial and chemical applications due to their resistance to heat and chemical exposure.

5. Steel and GI Pipes

Used extensively in oil and gas, construction, and industrial processing for their durability and high-pressure handling.

A reliable Pipes Company in India will not only offer these products but also provide technical consultation and customized piping solutions based on specific project requirements.

Key Features to Look for in a Pipes Company in India

When selecting a Pipes Company in India, it's important to evaluate them on several key parameters:

1. Product Quality and Certifications

Ensure that the company adheres to national and international standards such as BIS, ISO, ASTM, and ISI. Certifications guarantee consistent quality and safety compliance.

2. Manufacturing Technology

Modern pipe manufacturing techniques like extrusion, injection molding, and advanced quality control systems result in more durable and uniform products.

3. Product Range

The more comprehensive the product catalog, the easier it becomes to find solutions for varied projects, be it residential plumbing or industrial chemical transportation.

4. Distribution Network

An efficient distribution and logistics network ensures timely delivery across different regions, especially for large infrastructure projects.

5. Technical Support

Top Pipes Companies in India provide on-site assistance, training, and project-specific technical recommendations to help clients make informed decisions.

Applications of Pipes Across Industries

The versatility of modern pipes makes them suitable for various industries, each requiring unique specifications and standards. A professional Pipes Company in India typically caters to:

Real Estate Developers looking for cost-effective and corrosion-resistant plumbing systems.

Agricultural Sectors that require long-lasting irrigation systems to handle different water pressures and conditions.

Municipal Projects that need reliable piping for water supply, drainage, and sewage networks.

Industrial Sectors needing customized piping for transporting chemicals, gasses, or hot fluids.

Sustainability and Innovation in the Indian Pipe Industry

Sustainability is becoming a key differentiator in the industry. Forward-thinking Pipes Companies in India are adopting eco-friendly manufacturing processes, using recycled materials, and innovating to create more energy-efficient and leak-proof solutions.

New trends such as smart piping systems that can monitor flow and detect leaks are also emerging, providing value-added services and reducing long-term maintenance costs.

Additionally, companies are embracing digital tools and IoT integration to enhance the reliability and monitoring of piping systems, especially in large-scale commercial and industrial applications.

How to Choose the Right Pipes Company in India for Your Project

Here are a few tips to ensure you’re choosing the best partner for your piping needs:

Evaluate Experience and Market Presence Look for companies with a proven track record in delivering large and small-scale piping projects.

Check Client Testimonials and Reviews Feedback from previous customers can provide insights into product performance and customer service.

Assess Technical Capabilities Ensure the company offers value-added services like site audits, technical drawings, and pressure testing.

Compare Cost vs. Value Don’t just go for the cheapest option—consider long-term durability and maintenance requirements.

Visit Manufacturing Facilities (if possible) This provides a direct view of quality control measures and production processes.

Future of the Pipe Industry in India

The future looks promising for the Indian pipe industry. As urbanization, infrastructure development, and government-led schemes like “Har Ghar Jal” continue to expand, demand for high-quality piping will grow exponentially.

Pipes Companies in India are likely to focus on:

Increased automation and robotics in manufacturing

Greater use of composite and hybrid materials

Customization for niche industries

Sustainable sourcing and recycling practices

Conclusion

Selecting the right Pipes Company in India is not just about finding a supplier—it’s about partnering with an expert who understands your project needs, offers reliable products, and supports your goals for quality, safety, and sustainability.

With numerous options available, it's important to do your research and choose a company that combines innovation with experience, and quality with affordability. Whether you're building a high-rise apartment, planning an agricultural layout, or managing an industrial facility, your choice of piping partner can make a lasting impact on your project's success.

#drip irrigation india#water-efficient irrigation#drip irrigation solutions#indian irrigation manufacturers

0 notes

Text

One Stop Destination for Recycled Plastic Raw Materials for Quality Solution

At Plastmax (Thailand) Co., Ltd., we specialize in turning recycled plastic waste into high-quality raw materials tailored to meet the demands of industries worldwide. With over two decades of experience, our company is committed to innovation, sustainability, and customer satisfaction.

💡 What We Offer:

✔ LDPE Plastic Granules ✔ LLDPE Plastic Granules ✔ HDPE Blow Molding Granules ✔ HDPE Injection Grade Granules ✔ PP Injection Grade Granules ✔ ABS Plastic Granules ✔ HIPS Plastic Granules ✔ GPPS Granules ✔ PC / Polycarbonate Granules ✔ TPU Repro and Compounding

🏭 With a capacity of producing up to 30 tons per day, we cater to clients across automotive, packaging, and consumer goods industries in countries like India, Bangladesh, Ghana, Kenya, South Africa, and more.

✅ Why Choose Plastmax? • Customized plastic solutions • Strict quality control • Fast, reliable global delivery • Environmentally responsible processes 🔗 Visit Us: https://www.plastmax.co.th

#Plastmax#RecycledPlastic#SustainableSolutions#PlasticGranules#ThailandManufacturing#EcoFriendlyPlastics#RecyclingIndustry#PlasticRawMaterials

0 notes

Text

Industrial Check Valves Explained: Air, Hydraulic, and Water Pump Uses with Price

Industrial Check Valves Explained: Air, Hydraulic, and Water Pump Uses with Price

Check valves, also known as non-return valves (NRVs), are crucial components in industrial systems. They prevent back flow and ensure one-way fluid movement, protecting pumps, compressors, and pipelines from damage.

What is a Check Valve?

A check valve is a mechanical device that permits fluid (liquid or gas) to flow in one direction only. It automatically closes if the flow reverses, preventing contamination or damage to system components.

🔍 Quick Summary:

Prevents reverse flow

Protects pumps and compressors

No external control required

Types of Check Valves

1. Swing Check Valve

Hinged disc that swings open with forward flow

Best for horizontal pipelines

Common in water distribution

2. Lift Check Valve

Piston lifts vertically with pressure

Suitable for high-pressure flow

Ideal for clean fluids

H3: 3. Ball Check Valve

Uses a spring-loaded ball mechanism

Simple and compact design

Suitable for slurries and viscous fluids

4. Dual Plate (Wafer Type) Check Valve

Two spring-loaded plates

Compact and lightweight

Preferred in HVAC & chemical systems

5. Air Check Valve

Controls airflow in pneumatic systems

Prevents reverse air pressure

Used in compressors and tools

6. Hydraulic Check Valve

Manages oil flow in hydraulic circuits

Ensures pressure stability

Common in presses and lifts

Check Valve for Water Pump

Check valves are essential in water pump systems to prevent backflow and maintain pressure.

🔧 Uses:

Borewell and submersible pumps

Overhead tank systems

Booster pump sets

✔ Benefits:

Prevents dry running

Maintains pump priming

Increases overall efficiency

Check Valve Price in India (2025)

Valve TypeSize (Inch)MaterialPrice Range (INR)Swing Check Valve1" – 4"MS/CI₹250 – ₹2,000Lift Check Valve1" – 6"SS/CI₹300 – ₹3,000Ball Check Valve½" – 3"PP/HDPE₹100 – ₹1,200Wafer Check Valve2" – 8"SS304/316₹800 – ₹5,000Air Check Valve¼" – 2"Brass/SS₹150 – ₹1,800Hydraulic Check Valve¼" – 2"Steel₹300 – ₹2,500

📌 Prices vary based on material, pressure rating, and brand.

Applications of Industrial Check Valves

🔧 For Air Systems:

Pneumatic compressors

Air filtration systems

Automation tools

💧 For Water Systems:

RO plants

Irrigation systems

Industrial water lines

🛠️ For Hydraulic Systems:

Injection molding machines

Hydraulic lifts

Heavy industrial presses

H2: How to Select the Right Check Valve?

Choosing the right valve depends on several operational parameters:

✅ Key Factors:

Type of fluid (air, water, oil)

Operating pressure & temperature

Installation orientation

Valve size (e.g., 1-inch for domestic pumps)

Material compatibility (SS, CI, PP, etc.)

Advantages of Using Industrial Check Valves

Prevents back flow and contamination

Increases equipment lifespan

Reduces system maintenance

Supports safety and efficiency

FAQs – Check Valve

Q1. What is a check valve used for?

A check valve allows one-way flow and prevents reverse flow in pipelines, protecting pumps and compressors from damage.

Q2.Which check valve is best for water pumps?

Swing and lift check valves are preferred for water pumps due to their low-pressure drop and ease of maintenance.

Q3. Are check valves and NRVs the same?

Yes, NRV stands for Non-Return Valve, which is another name for a check valve used commonly in India.

Q4. What size is a 1-inch check valve used for?

1-inch check valves are ideal for small pumps, domestic water lines, and irrigation systems.

Q5. Can check valves be used for air?

Yes, special air check valves are designed for compressed air systems to prevent back-pressure.

0 notes

Text

How to Choose the Best Plastic Fabrication Company for Your Manufacturing Needs

In today's competitive market, finding the right plastic fabrication company is crucial for businesses that require high-quality, durable, and cost-effective plastic components. Whether you need custom plastic parts for industrial applications, retail products, or specialized manufacturing, selecting the right company ensures efficiency, reliability, and long-term success. Here’s a comprehensive guide to help you choose the best plastic fabrication company for your needs.

1. Assess Your Project Requirements

Before searching for a plastic fabrication company, clearly define your project’s needs. Consider the following factors:

The type of plastic materials required (e.g., acrylic, polycarbonate, PVC, HDPE, etc.)

The complexity of the design and required tolerances

Volume and production scale (small batch vs. mass production)

Intended application and environmental considerations (e.g., heat resistance, UV protection, impact strength)

By understanding these specifics, you can narrow down your options to companies that specialize in your required fabrication methods.

2. Evaluate Fabrication Capabilities and Techniques

Different plastic fabrication companies offer a range of manufacturing techniques. It’s essential to choose a company with the right capabilities for your project. Some common fabrication techniques include:

CNC Machining – Ideal for precise and complex parts with tight tolerances.

Thermoforming – Suitable for large plastic sheets molded into specific shapes.

Injection Molding – Best for high-volume production of uniform plastic components.

Extrusion – Used to produce long plastic profiles like tubes and rods.

3D Printing – Beneficial for prototyping and low-volume production.

Ensure that the company you choose has expertise in the method that best suits your needs.

3. Check Industry Experience and Reputation

Experience plays a significant role in the quality and reliability of plastic fabrication services. Look for companies with a proven track record in your industry. Some key indicators of a reputable company include:

Years in business and industry experience

Client testimonials and case studies

Certifications such as ISO 9001 for quality management

Compliance with industry-specific regulations

A company with a strong reputation and experience in handling similar projects is more likely to deliver consistent quality and meet deadlines.

4. Assess Material Quality and Supplier Network

The quality of plastic materials significantly impacts the durability and performance of your final product. Ensure that the company sources high-grade materials from reliable suppliers. Ask about:

Material certifications (e.g., FDA compliance for food-grade plastics, UL ratings for electrical applications)

Recycling and sustainability practices

Availability of specialized materials such as flame-retardant or medical-grade plastics

Working with a company that prioritizes high-quality materials ensures that your products will meet industry standards and customer expectations.

5. Examine Their Quality Control Processes

Quality assurance is a crucial factor in plastic fabrication. The best companies implement strict quality control measures throughout the production process. Some aspects to look for include:

In-house testing and inspection protocols

Use of advanced measurement tools (e.g., CMM, laser scanning)

Compliance with international quality standards

Corrective action policies in case of defects

A company with robust quality control ensures that every part meets the required specifications, reducing the risk of defects and production delays.

6. Consider Customization and Design Support

If your project requires custom parts or unique designs, choose a company that offers design support and prototyping services. Many top-tier plastic fabrication companies provide:

CAD design and engineering assistance

Rapid prototyping for design validation

Tooling and mold-making services

Collaborative problem-solving for complex projects

A company with strong design and customization capabilities will help optimize your product for manufacturability and cost efficiency.

7. Evaluate Production Lead Times and Scalability

Timely production is essential to meet market demands and maintain a smooth supply chain. Ask potential fabrication partners about:

Average lead times for different project sizes

Scalability options for future growth

Their ability to handle urgent or rush orders

Selecting a company that can scale production according to your needs ensures long-term reliability as your business grows.

8. Compare Pricing and Cost Transparency

While cost is an important consideration, it shouldn’t be the sole deciding factor. Look for companies that offer competitive pricing without compromising on quality. Request detailed quotes and compare:

Material costs

Production and labor charges

Tooling and setup fees

Shipping and logistics costs

Ensure the pricing structure is transparent, with no hidden fees or unexpected charges.

9. Check Customer Service and Communication

Effective communication is vital in any business partnership. Choose a plastic fabrication company that is responsive, transparent, and willing to collaborate. Key factors to consider include:

Availability of a dedicated account manager

Clear and timely updates on project progress

Willingness to address concerns and make necessary adjustments

A company with excellent customer service fosters a smooth working relationship and ensures that your expectations are met.

10. Review Sustainability Practices

With increasing emphasis on environmental responsibility, consider working with a company that follows sustainable practices. Ask about:

Use of recycled or eco-friendly materials

Waste reduction and energy-efficient manufacturing processes

Compliance with environmental regulations

Partnering with an eco-conscious company can enhance your brand’s reputation and contribute to sustainability goals.

Choosing the right plastic fabrication company requires careful consideration of various factors, from technical expertise and material quality to pricing and sustainability. By conducting thorough research and assessing potential partners based on these criteria, you can ensure a successful collaboration that meets your manufacturing needs while maintaining high product quality. Take the time to evaluate your options, request samples, and engage in discussions with potential suppliers to make an informed decision. With the right fabrication partner, your business can achieve efficiency, cost savings, and long-term growth.

0 notes

Text

HDPE Bottle Manufacturers: Innovating Sustainable Packaging Solutions

High-Density Polyethylene (HDPE) bottles have emerged as a preferred packaging solution across diverse industries, including pharmaceuticals, food and beverages, cosmetics, and chemicals. Their exceptional durability, lightweight composition, and recyclability make them a sought-after option. As environmental consciousness grows, manufacturers are integrating sustainable practices to align with regulatory standards and consumer expectations.

The Importance of HDPE in Packaging

HDPE offers remarkable strength, impact resistance, and chemical stability, making it an ideal material for liquid and semi-solid storage. Its moisture, chemical, and UV resistance ensure product integrity over time. Moreover, HDPE is free from BPA and fully recyclable, making it a superior alternative to conventional plastics.

Leading Manufacturers of HDPE Bottles

Globally, numerous manufacturers specialize in producing high-quality HDPE bottles, utilizing advanced molding techniques such as extrusion blow molding and injection blow molding. Many leading companies provide tailored packaging solutions to meet specific industry needs while adhering to stringent quality and safety standards.

Key Considerations When Selecting an HDPE Bottle Manufacturer

Businesses should evaluate the following aspects when choosing an HDPE bottle supplier:

Quality Compliance: Ensure the manufacturer meets international safety and quality standards such as ISO certifications and FDA regulations.

Customization Capabilities: Opt for a supplier that offers personalized bottle designs to fulfill unique branding and functional requirements.

Eco-Friendly Initiatives: Select a manufacturer committed to sustainability through the use of recycled materials and responsible production methods.

Cost Efficiency: Balance affordability with superior quality to ensure long-term value.

Reliable Supply Chain: A dependable manufacturer should guarantee timely bulk deliveries to maintain operational efficiency.

The Future of HDPE Bottle Production

With an increasing focus on sustainability, HDPE bottle manufacturers are investing in innovations like biodegradable additives, post-consumer recycled (PCR) plastics, and lightweight designs to minimize material usage. Technological advancements are also enhancing energy efficiency and reducing production waste, making HDPE bottles an even more sustainable choice for packaging applications.

Conclusion

HDPE bottle manufacturers play a pivotal role in modern packaging, delivering durable, cost-effective, and eco-conscious solutions for multiple industries. As the demand for sustainable packaging rises, companies must continuously innovate and implement greener production methods. Choosing a reputable HDPE bottle manufacturer ensures superior packaging while supporting global sustainability efforts.

0 notes